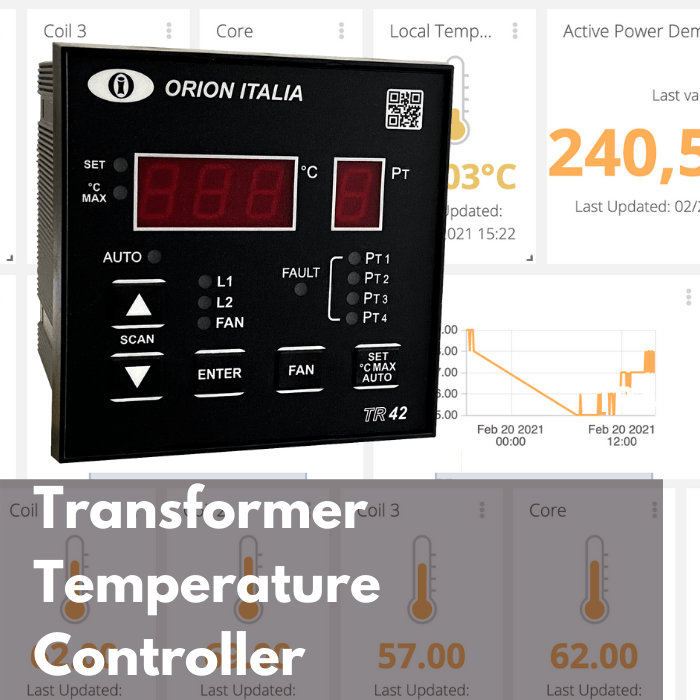

Transformer Temperature Controller

Cast Resin Transformer information

Transformer Temperature Controller

In any electrical system it is very important to maintain it without power outages, the transformers are a fundamental part and the temperature must be constantly controlled. A transformer temperature controller must be installed to perform this monitoring and control function. Using Pt100 temperature probes, the current temperature of each winding is measured and the temperature controller compares it against the temperature setting, basically it turns on fans to lower the temperature of the windings, gives an alarm signal and in the worst case trips the transformer to ensure the safety of people and assets.

At Orion Italia we are experts manufacturing protection relays for transformers and other electrical applications, our temperature controller device has been installed in thousands of resin and dry transformers around the world, in all types of environments (hot, cold, humid, dry), to learn more about our TR42 click on the following link:

Dry Type Transformer Temperature Controller

Dry type transformers have a temperature rise of 150 °C, 115 C or 80° C, based on 40 °C ambient temperature, depending on these values the temperature controller for dry type transformer must be set. Setting for alarm and fan start levels are mandatory, as well as trip with a higher temperature value than the previous ones.

When a dry type transformer start into operation, the calculation of the temperature protection setting must be made to enter it in the temperature controller device, the document “Electrical Protection Relay Settings and Coordination” include all the

relay settings calculations, other values and transformer temperatura settings as well.

Cast Resin Transformer Temperature Controller

The objective of a temperature controller for casr resin transformer is to keep the temperature below the operating limit defined by the manufacturer, to avoid overloads and overheating, so that the useful life of the transformer (usually 20 or 25 years) is not minimized. .

Near the transformer will be the control panel with its control cables and other elecrtrical parts, there will be the temperature controller for cast resin transformer, with a led screen and buttons

to access the settings. At least the following will be adjusted:

- Alarm: a first temperature level to indicate that we are close to over temperature or overload.

- On / Off Fans: a second temperature level that will turn on forced ventilation, for cooling transformer windings.

- Trip: a third temperature level (the highest of the 3) that disconnects the transformer due to over temperature to avoid internal damage and risks to the building and people.

The temperature controller is measuring the current temperature of the windings and compares it against the setting programmed, all this constantly, in case of rising or falling from those set levels, it opens or closes digital outputs to give the necessary commands for the correct operation of the electrical installation, all these values can also be sent through the RS-485 Modbus communication port and converted to Ethernet, connected to a SCADA, Cloud electrical information system, PLC or any digital/computer system.

How does a temperature controller work?

It is an electronic device that is used to control the temperature within a range or below / above a desired setting, it does so by calculating the difference between the measured temperature and the setting.

For dry or cast resin transformers, the temperature controller measures the temperature of the windings and in case of exceeding the setting, it activates their digital outputs turning on forced ventilation to cool the transformer and solve the over

temperature detected.

What temperature should a transformer run at?

They must operate within the limits indicated by the manufacturer and are defined over an average temperature of 40 degrees Celsius (°C). The "rise temperature" is added, which is reached at nominal power, in the case of dry transformers it is 80 °C, 115 °C or 150 °C, and generally the material of the windings is designed for 220 °C (which gives margin for occasional overloads or overheating), for oil transformers the “temperature rise” is 55 °C / 65 °C.

Let's look at these 2 examples for dry type transformers:

1- Dry transformer with rise temperature of 80 °C, ambient temperature* of 40° C, at nominal power its temperature will be 120° C, because the material of its windings is designed for 220 °C we have a wide margin for occasional overloads / overheating (without damaging the insulation or affecting the life of the transformer).

* If the average ambient temperature is 20 °C, at full load we will have 100 °C, with which we have even more margin until reaching hot temperatures in the transformer.

2- Dry transformer with a rise temperature of 150 °C, ambient temperature** of 40 °C, at nominal power its temperature will be 190 °C, due to the fact that the material of its windings is designed for 220 °C we have a

small margin for occasional overloads / overheating.

** If the average ambient temperature is 45 °C, at full load we will have 195 °C, which will further

reduce the margin until reaching overheating and hot spots in the transformer.

What is the price of a temperature controller?

Its price is defined by the functions it performs, the communication capabilities it has, the flexibility of parameterization, as well as the precision and other technical characteristics.

Our TR42 temperature controller for dry and cast resin transformers is a device with a very competitive price, since it has all the capabilities to control the temperature of the transformer windings by monitoring the temperature using Pt100 probes and the activation of fans to generate a forced air flow dissipating the heat produced by the energy consumed by the loads, it also includes extras such as communication through the RS-485 Modbus port, there is also an option of 4-20mA inputs.

The price of a temperature controller will start from one basic equipment to another with all the possible extras, as it has more functions, its price will increase. The complete technical details of a transformer temperature controller are in the datasheet, usually in pdf format.

Download Technical data:

- Manual for transformer temperature controller relay TR42 in PDF.

What is a temperature indicator controller?

It is a device that shows on a screen the actual temperatura and any other relevant parameters that the controller is monitoring (usually it is integrated into the same equipment that running the temperature controller functions). The temperature controllers of dry type or cast resin MV / LV transformers are digital and have a led display where they show the measured temperatures of each winding, as well as data on settings, configuration, status of the temperature probes and any other relevant parameters that may be present associated with this temperature control.

For detailed information, check at this web page PDF Manual:

What is temperature in control system?

The temperature in a control system or checking and managing the temperature through a control system is a common process, it requires measuring the temperature, and executing actions to change it, in addition to a cooling system. For dry or cast resin transformers generally this control system is integrated in the transformer temperature protection relay.

The main objective of this system is to turn off or on the fans to

decrease the temperature of the windings when they exceed a predetermined setting, by means of forced air circulation, there may be several levels of adjustments to increase the power of the forced air flow.