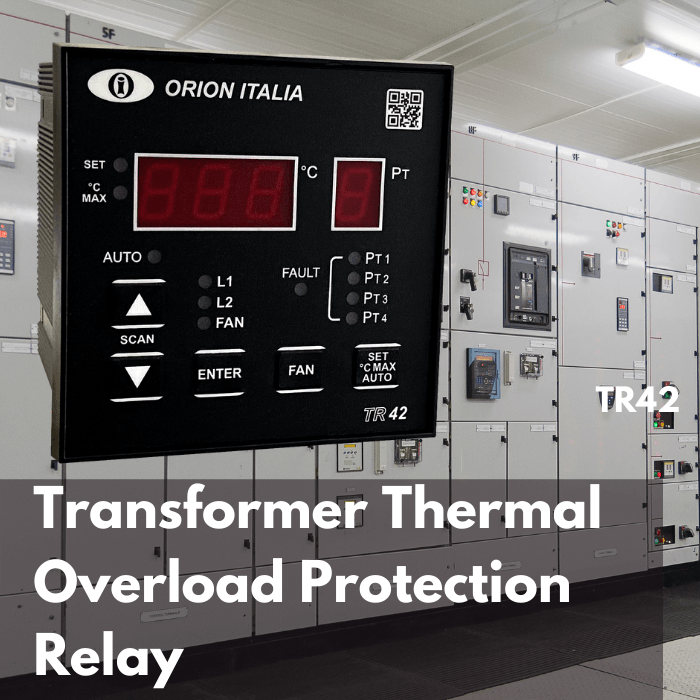

Transformer Thermal Overload Protection Relay

Transformer Thermal Overload Protection

Transformers are significant assets and a very important part of the electrical system, any failure in these can cause power outages or security risks, due to this, transformer thermal overload protection relay (ansi 49) must be installed. This protection is closely linked to temperature and overload, within the protection relay there is a mathematical model that predicts the thermal situation of the transformer at all times.

In a dry-type or cast resin transformer, temperature and current are the most important variables to control, at

Orion Italia we are experts manufacting protection relays, thousands of units installed around the world in the most varied ambient temperature conditions, to learn more about our relay temperature protection for transformers click the following link:

Transformer Thermal Protection Relay

A thermal protection relay for transformers is a device capable of estimating the thermal overload by means of a mathematical model based on the transformer load (current), as well as the temperature. Currently the protection relays are digital, based on a microprocessor (or microcontroller), this has considerably improved the electrical sector by having more precise devices, with a low failure rate and available to operate in all types of environments, even remotely.

These relays can integrate not only the

transformer thermal protection, but some more, in addition to other functions, historical, auxiliary contacts for alarms, trips and automatisms, it is also very common to have a communication port to integrate them with remote computer systems, since whether within the same facility, control centers in a remote location or cloud software, all to improve asset management, reduce power outages and increase the safety of people and buildings.

Transformer Overheat Protection Using Thermal Sensor

Over heat in dry-type and cast resin transformers can be caused by different situations: overload, high ambient temperature, poor ventilation, internal faults and other electrical conditions, also due to the combination of these factors. An overheating protection with a thermal sensor (temperature probes as PT-100) must be installed for a direct measurement of this temperature in the windings and thus be able to control and monitor it.

Depending on the level of overheating (excess temperature) and its duration, it can affect the life of the transformer, its performance, cause degradation of its internal parts, power outages or even be a risk to the safety of people and buildings. The transformer's over-temperature protection has set a series of values for which it activates or deactivates forced ventilation (fans) through auxiliary contacts; there are also auxiliary contacts for alarm and tripping. The measurement of these thermal sensors, as well as other values of the protection relay can be integrated into remote computerized systems, such as SCADA, electrical software, or cloud computing systems.

The following list is clickable for additional information about related products:

- PT100 Thermal Sensor

- PT100 Junction box for Thermal Overload Protection Relay

- Dry Type Transformer Over Heat Panel Board (Ready to Mount)

Transformer Thermal Relay 49

Protection against thermal damage in transformers (oil, cast resin, dry type) is specified under ANSI 49, that is, thermal relay 49 for transformers, also under this section are the thermal protections of motors and generators.

By means of a mathematical model carried out with programming in microprocessors / microcontrollers (it is the basis of all digital relays), calculations are carried out to analyze this thermal capacity to which the transformer is subjected due to the current and ambient temperature, as well as any other important data that can bring an improvement to the numerical model.

The temperature relays for dry type and cast resin Transformers are a different kind of protection, because they only use direct measurement, since they have connected sensors installed in the windings and to directly monitor the temperature in each winding by measurement.

Transformer Thermal Overload Relay

A

transformer thermal overload relay uses a model to estimate the overload based on temperature sensors, nowadays digital relays are specially designed to perform this type of calculations where temperature and overload are closely related. The "thermal" concept is usually associated with bimetals, which are heated by the effect of temperature increase until they separate or activate a contact at a desired temperature. A thermal protection relay usually disconnects the transformer quickly when there are values that are above the safe operation of the transformer.

How do you protect a transformer from heat?

It is protected by measuring the temperature, to take actions such as activating forced ventilation or the cooling circuit, activating alarm signals (to reduce power or balance loads with other transformers), or in extreme cases by tripping the transformer to avoid damage.

The most used method to reduce the heating of a dry / cast resin transformer is to activate forced ventilation using fans, so that a stream of air circulates between its windings and lowers its temperature, also sometimes the enclosure (or room) where the transformer is located can be ventilated by means of the opening doors / windows, so that air from outside enters and expels hot air.

The most widely used method is to install fans activated by a temperature controller that measures the temperature in the windings. There can be several fans, disconnecting or connecting depending on different predefined temperature settings.

Overheating Protection of Transformer

Overheating of a transformer can cause damage, so equipment is installed to control the temperature in its windings. Overheating protection in dry-type and cast resin transformers is done with a temperature protection relay by means of Pt100 sensors installed in the windings, in these transformers the material of the windings is designed to withstand up to 220 °C, from there it is degrades the material, it is not necessary to allow these high levels of overheating, the temperature protection settings will be done according to the manufacturer's information about "temperature increase", which in the case of this type of transformer has 3 levels: 80 °C, 115 °C, 150 °C. (based on 40 °C average annual ambient temperature).

Dry type & Cast Resin Transformer Thermal Overload Protection

In all transformers, a protection against thermal overloads must be installed, for dry type and cast resin transformers these protections are simpler, but therefore no less efficient, robust, they must be highly reliable protections since they protect machines that feed important loads that must operate safely.

Cast Resin and Dry type transformers are usually MV / LV, feeding all types of loads: shopping centers, buildings, industries, schools, hospitals, residential centers, auxiliary services in industrial and power generation plants, among many other uses, the Installation of a

thermal overload protection relay will act to maintain equipment operation in safe operating ranges, so as not to reduce the useful life of the transformer and operate in safe conditions for people and buildings.