Transformer Temperature Control

Transformer Temperature Control

Transformers are the most important equipment to maintain the continuity of the electrical system, in case of failure of a transformer it is very likely that there will be power outages to the loads that it feeds, this should be avoided by making all possible efforts since it produces costs due to inactivity, maintenance and repairs.

Transformer temperature control is mandatory to maintain electrical service with the best possible energy quality and reduce overheating and overload failures, as well as extending service life by working within a controlled temperature range. The temperature of a transformer gives us information about its "health", efficiency, power and load.

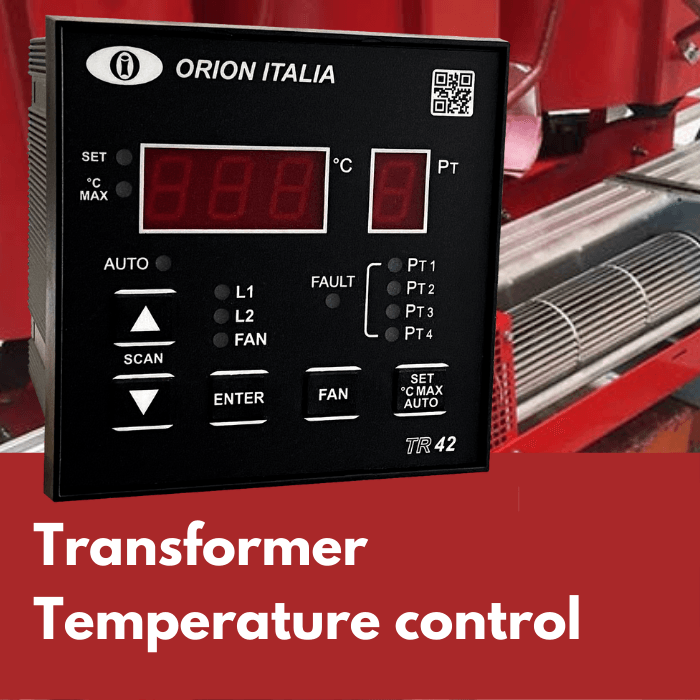

For more than 35 years Orion Italia has manufactured protection relays for electrical systems of all kinds, our TR42 temperature protection device is installed in hundreds of thousands of transformers around the world. For more information about this product and get a pdf manual click on the following link:

Transformer Temperature Control Unit

To measure the temperature of a transformer, whether with RTD, PT100, Fiber optic, RF Wireless or infrared, it is necessary to have a temperature control unit capable of interpreting these signals and converting them into real temperature values, generally it is a digital device ( microprocessor-based) with internal programming, customizable settings, inputs / outputs and communication port, these transformer temperature control units perform the complete management to maintain the temperature of the windings at adequate operating levels, always within the range specified by the manufacturer.

The transformer temperature control unit generally has RS-485 Modbus RTU communication port to allow integration into higher level systems such as SCADA, substation control or cloud electrical information systems, it

can also be integrated with PLC in industrial applications.

Transformer Temperature Control System

The set of sensors, control unit, software, settings, fans, wiring, even systems connected by communications (RS-485 / Ethernet) and everything necessary to control the temperature of a transformer is called

“transformer temperature control system”,

that is, it include a collection of elements that are integrated in order to maximize the efficiency of transformers, minimize thermal stress, failures, optimize maintenance planning and extend the useful life of these assets.

Cast Resin Transformer Temperature Control

Cast Resin transformers are a critical element of the electrical system where it is installed, they are generally MV / LV, directly feeding important loads, therefore we must install a transformer temperature control, to keep the temperature within the range indicated by the manufacturer and In case the measured value is above the setting, this control commands to turn on the fans and force the air flow between the windings to dissipate the heat generated.

Dry Type Transformer Temperature Control

We must try to extend the life of assets for as long as possible in optimal operating conditions. Dry transformers are generally designed to convert medium voltage to low voltage and are the key equipment for supplying low voltage loads. Install a transformer temperature control device is mandatory to maximize the quality of electrical service, minimize power outages and operate each transformer within the desired temperature range,

preventing overheating, by activating forced air flow (using Fans).

What are temperature control units?

It is the unit that controls the temperature of an industrial system, for transformers its objective is to keep the temperature in the windings below a previously configured setting.

The temperature control unit is usually digital, based on a microprocessor, the dry and resin transformers integrate this temperature unit in the temperature protection relay, with the advantages that this can offer, since a record of the temperatures over time, turn forced ventilation on or off depending on the temperature measured in each winding, send alarms or remote signals, in addition to tripping the power breaker in case of exceeding the maximum desired temperature.

How do you measure the temperature of a transformer?

The temperature is measured by a thermometer that is composed of a sensor, either RTD (resistance temperature detectors), these generally a PT100 platinum probe, thermocouples and sometimes fiber optics is also used, even infrared sensors.

The temperature in dry or cast resin transformers is measured by means of PT100 probes, as it is made of platinum, the resistance in each degree of temperature is perfectly defined, a sample of these values are:

| Temperature in °C | Pt100 (typ: 404) in Ohm |

|---|---|

| -10 | 96.09 |

| 0 | 100.00 |

| 10 | 103.90 |

| 50 | 119.40 |

| 100 | 138.50 |

| 150 | 157.31 |

For detailed information, check at this web page PDF Manual:

What is temperature in control system?

The temperature in a control system or checking and managing the temperature through a control system is a common process, it requires measuring the temperature, and executing actions to change it, in addition to a cooling system. For dry or cast resin transformers generally this control system is integrated in the transformer temperature protection relay.

The main objective of this system is to turn off or on the fans to

decrease the temperature of the windings when they exceed a predetermined setting, by means of forced air circulation, there may be several levels of adjustments to increase the power of the forced air flow.

What are the methods of temperature control?

There are different methods and devices available to control the temperature, the most common are:

- PT100 sensors: they are the heart of the temperature acquisition, a Pt100 is a temperature sensor formed by a platinum wire that at 0 ° C has 100 ohms and that when the temperature increases its electrical resistance increases, in the whole range of temperature, its resistance increase is not linear, but if the resistance value for each exact temperature degree is defined exactly in tables

- Measurement and control equipment: it is a digital device with inputs for the temperature sensors, which translates and analyzes this values in real time, this device is responsible for turning on or off forced ventilation in the case of cast resin or dry transformers with the aim of circulating air and reducing the temperature in the windings through the flow of air.

- Ventilation System: it is formed by the fans that will make the air flow towards the windings, it also includes its metallic structure and wiring.

- Room Cooling: on some occasions it is possible change the ambient temperature of the room where the transformers are located by natural means, such as the opening of doors and windows, to allow the outside temperature to enter the room where the transformers are located, Depending on the country and season of year, it is a natural solution to modify the temperature of the windings by several degrees without the need for forced air, sometimes both methods are used together.